About us

Maforsa

The Beginning

The two owners, Jaime Arrieta and José Cox have been involved in the lumber business since 1985. In 1994 they founded Maforsa, to supply the domestic and North American markets with primed MDF and Radiata Pine moldings. In 1999 they created and developed the MDF wall covering (wainscot) consolidating, with an innovative process and product design, their leadership in the market as a solution provider tailored to their customers.

Our Growth

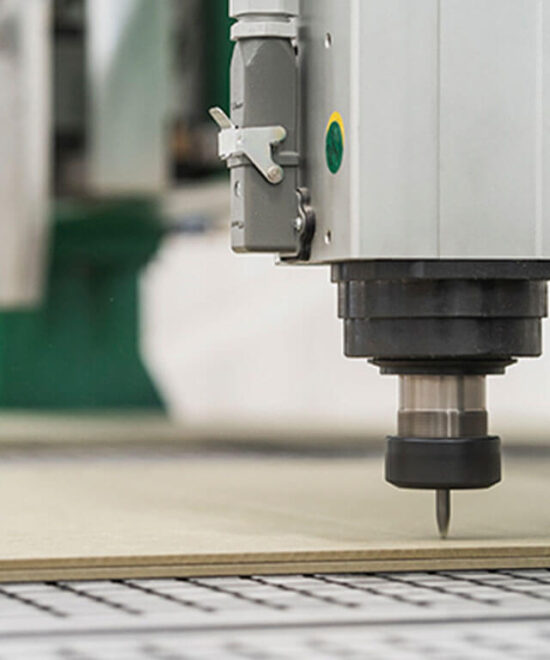

Maforsa continued investing and innovating, launching in 2010 its first two wrapping lines to produce paper and veneer wrapped mouldings, with a capacity of 500,000 linear meters per month. In 2018 the company added 60,000 square feet of new buildings to stock more raw materials and finish products. In 2020 Maforsa start operating a new door plant with a capacity of 40,000 doors per month.

An ally for Chile and the World

Since 1994, Maforsa has been creating and manufacturing superior moulding & millwork products for the domestic and export markets. The product line now include more than 500 different profiles of casing, baseboards, crowns, shiplap and wainscot. Our Mega Centre located in Lampa, Chile, includes a primed moulding plant, a wrapped moulding plant, a distribution center and a new door plant. From our distribution center we serve the domestic retail and industrial markets. Our international customers, mainly from North America, are moulding and millwork wholesalers that have found in Maforsa a relialable link in their supply chain.